Open wechat

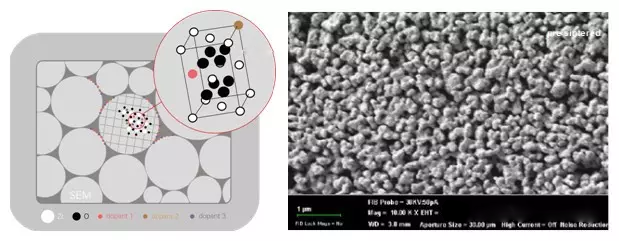

Open wechatZirconia dye is like a cocktail of metal oxides

And the secret of success is:

-Balance the proportion of various additives

-Ensure that the color of additives is evenly distributed in the lattice

-Avoid reducing intensity

During the sintering process, metal ions / additives enter into the grain boundary and zirconia lattice. The final dyeing effect depends on the absorption of metal ions and the reflection of light at the grain boundary.

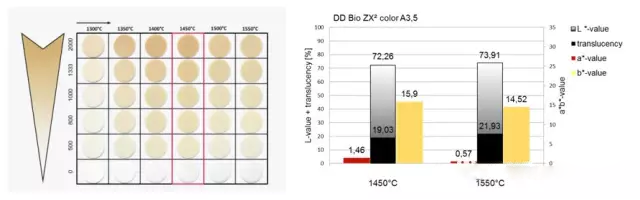

When the mineral reaches a certain temperature, the color begins to appear. When the mineral reaches a predetermined temperature, the preset color appears. Once the design temperature is exceeded, some minerals added in the zirconium block begin to disappear, and the color becomes lighter and yellowish. At the same time, the higher the sintering temperature, the higher the transparency of the crown.

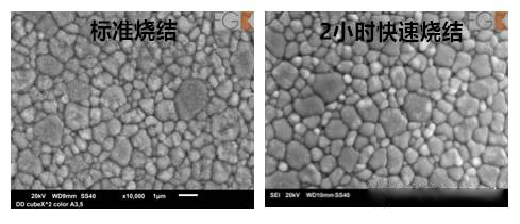

Effect of fast burning on color and intensity

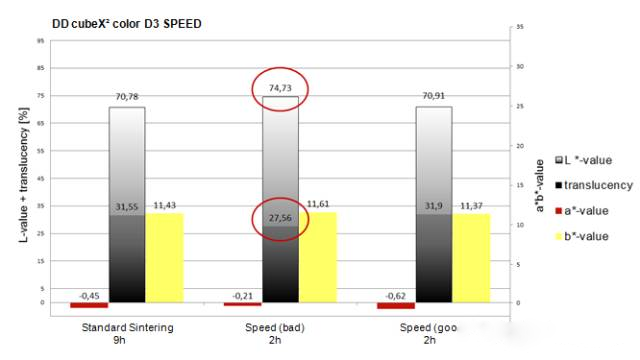

With the increasing pace of work, it is difficult for traditional standard sintering to cope with some unexpected situations. More and more sintering furnaces and zirconia suppliers are constantly cooperating with each other and have achieved certain results.

German dental Direkt company has done a lot of experimental research on this, and found that the same material in different sintering furnace sintering, because of their different sintering atmosphere, the sintering results are often very different. Next, we compare the results of different sintering furnaces in terms of l-value, A-value, b-value and transparency.

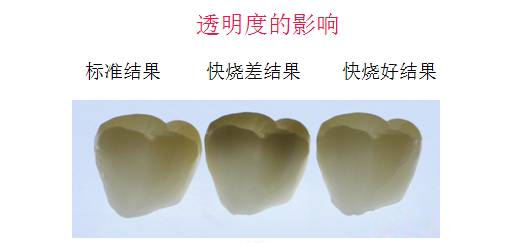

It can be seen that in poor sintering atmosphere, the transparency, lightness and hue are very different from those of standard sintering. This difference eventually leads to a crown with dark lightness, yellow hue and unsatisfactory transparency.

And in a better sintering atmosphere, there will still be some subtle differences.

In short: how to get stable transparency, color effect?

-Make sure your sintering furnace has no color pollution

-Ensure the stability of sintering furnace

-Operate in strict accordance with the operation procedures specified in the material specification